Case study: High-pressure VS. Low pressure

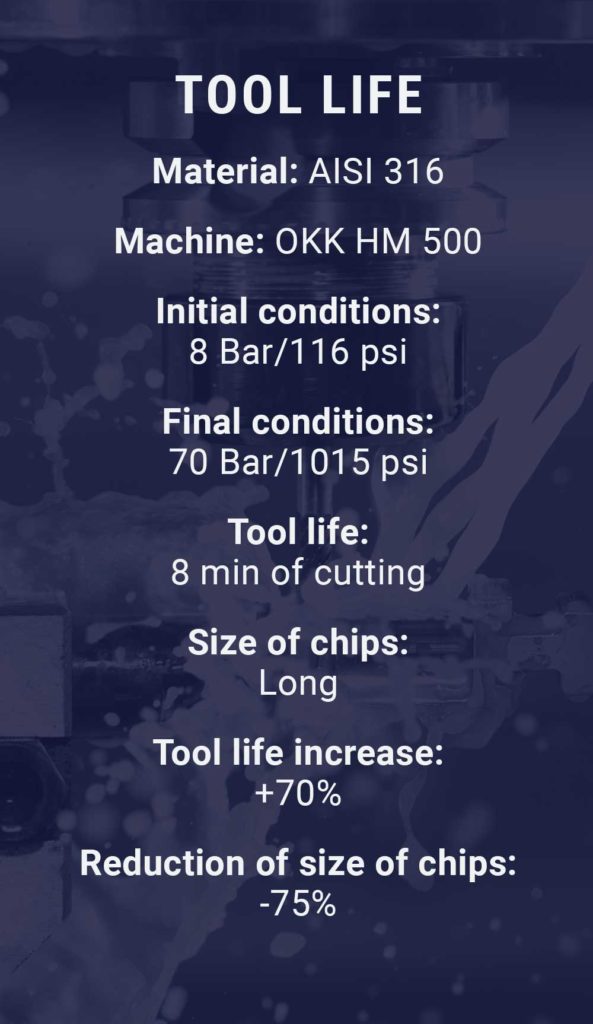

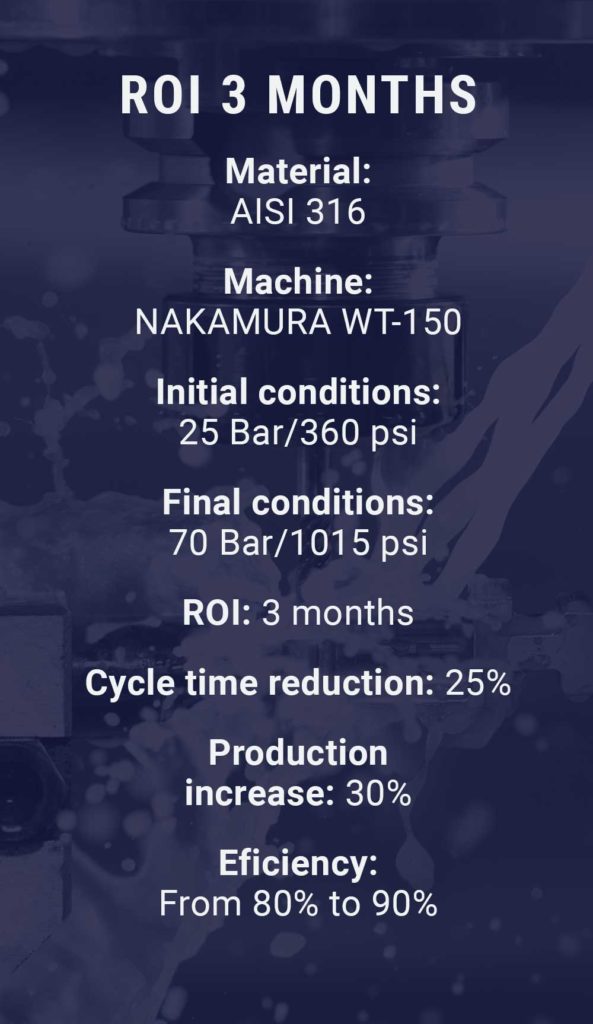

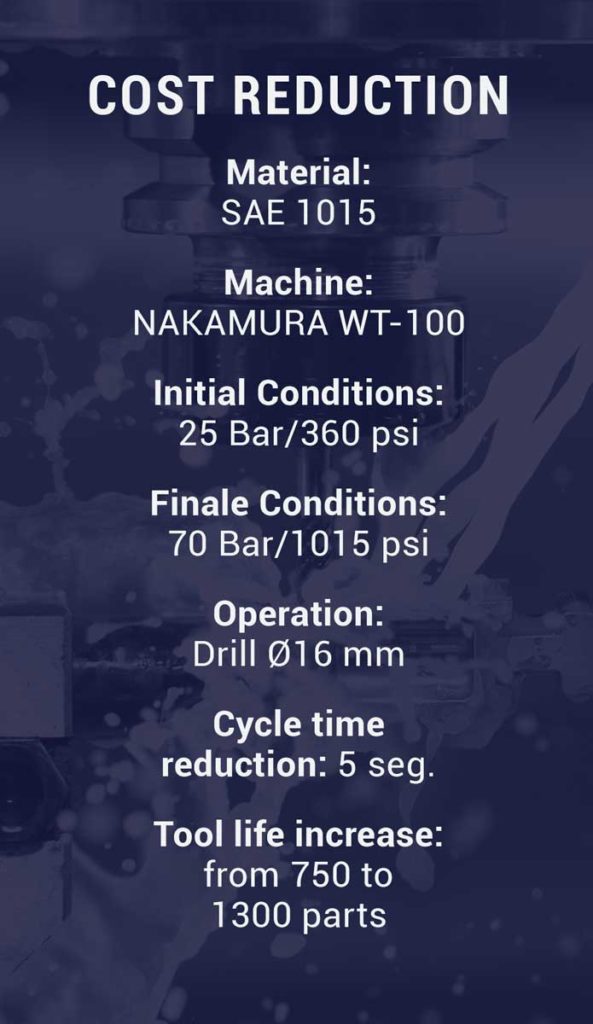

Case study: High-pressure VS. Low pressure Initial conditions Material to be machined: AISI-316l/EN14404. Part used: Bar Pre-drilled 236 mm outer diameter and 150 mm inside diameter. Machine used: Multiprocess turning center. Coolant used: Emulsion at 7%. Depth of cut conditions “ap” and feed per revolution “fn”: fixed by the manufacturer; ap= 0.4 mm – fn= […]

Case study: High-pressure VS. Low pressure Read More »