Our SCS series

SCS SERIES HIGH-PRESSURE SYSTEMS

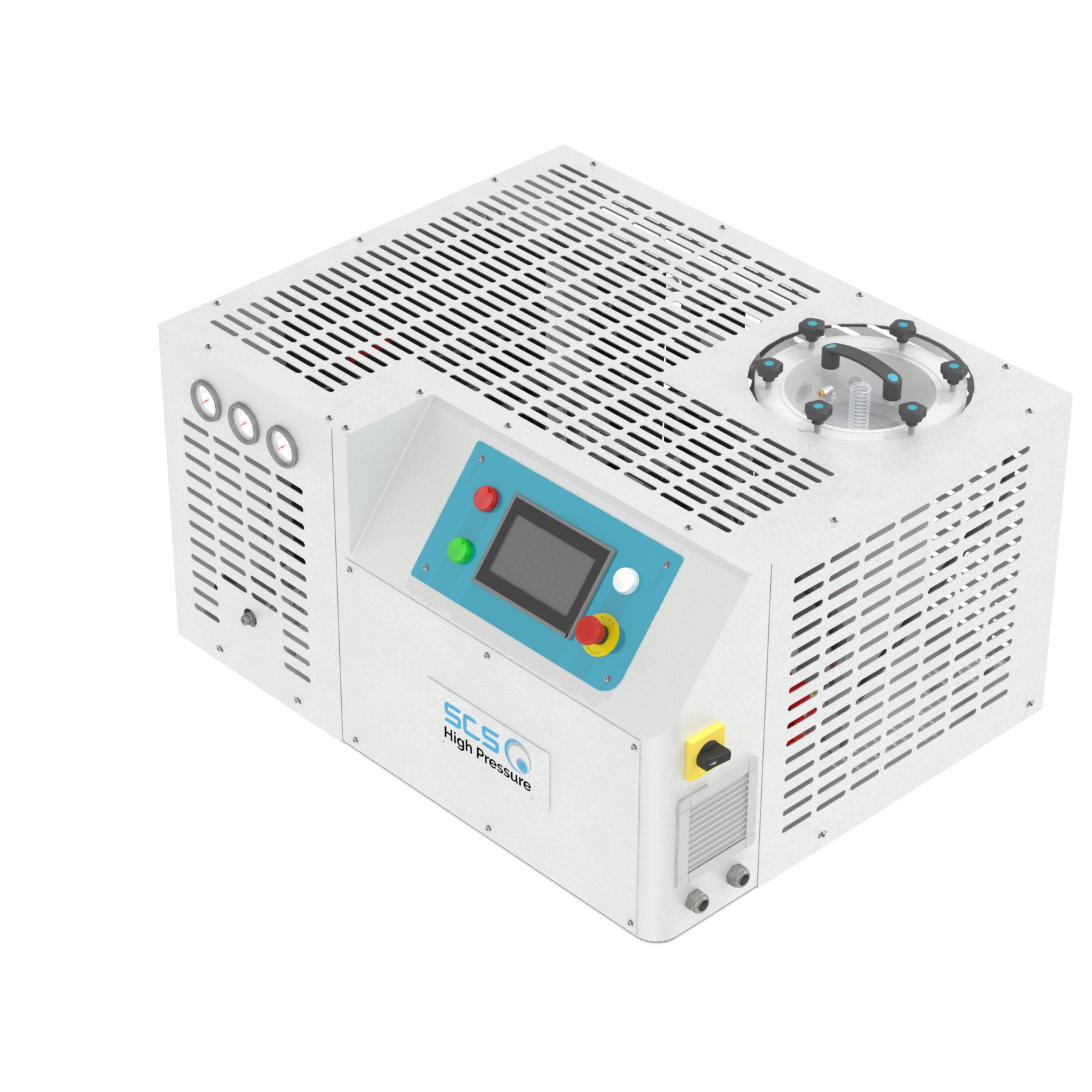

SCS 90 | OIL / EMULSION

Simple and strong High pressure unit, designed to cope with entry level demand. Easy to install, basic features and high quality pressurized filter and HP pump. Works for small MC, single turret Lathes and small Swiss type lathes.

Features:

- Pressure: from 50 / 135 Bar (725 – 1958 psi)

- Flow: from 23 / 40 l/min

- High-pressure outlets: 1(optional up to 8)

- Filter: Bag type 5 μm

- Tank capacity: 180 L

- Heat exchanger: Not included

SCS 200 | OIL

Compact HPC unit for sliding head machines, designed to fit under most of Barfeeders. it does not have a tank and works with a pressurized filter connected directly to the machine-tool tank. Works for small Swiss type lathes and small fix head lathes.

Features:

- Pressure: from 70 / 135 Bar (1015 – 1958 psi)

- Flow: from 23 / 24 l/min

- High-pressure outlets: 1(optional up to 8)

- Filter: Bag type 5 μm (Pressurized Filter)

- Tank capacity: Without tank

- Heat exchanger: Not included

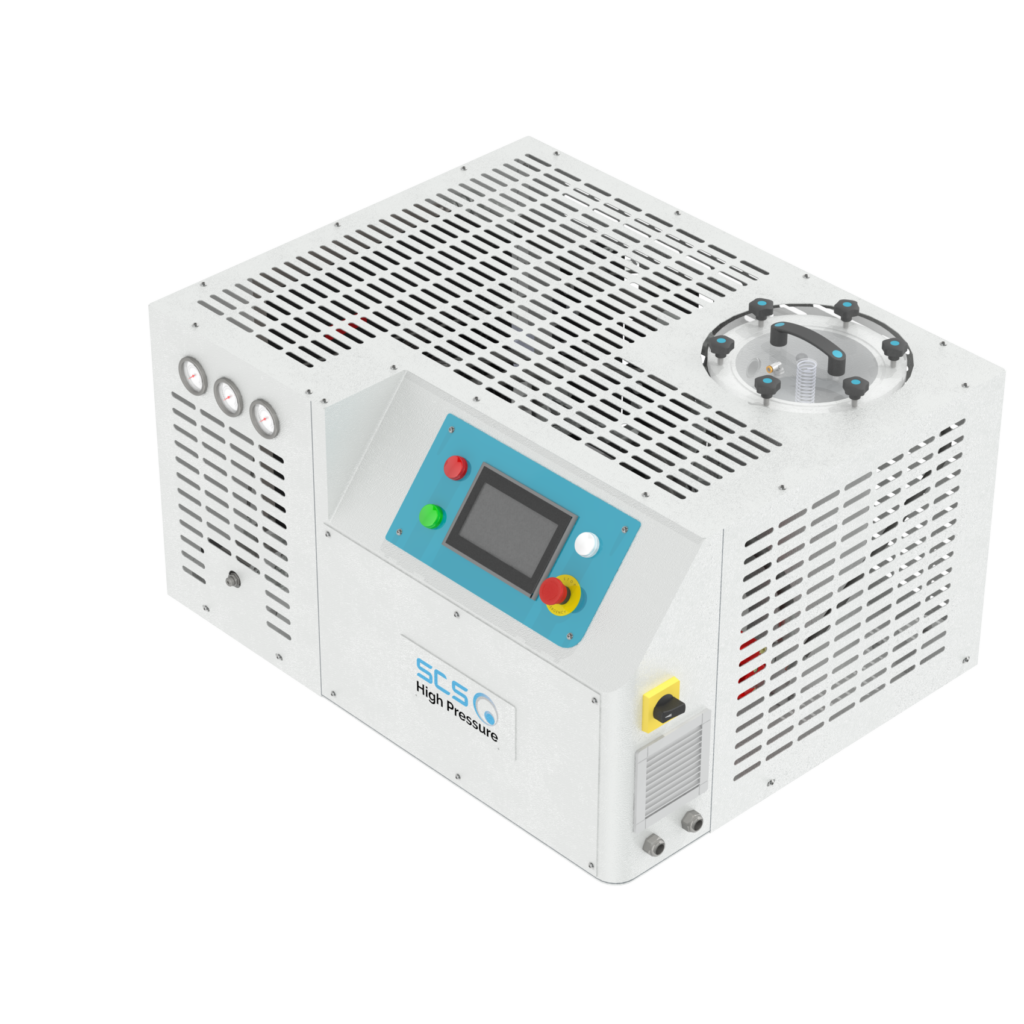

SCS 300 | OIL / EMULSION

High featured HPC. Fits under Iemca Bar feeder and other models too. Compact unit very versatile for Swiss type lathe of high specs.

Features:

- Pressure: from 70 / 135 Bar (1000 – 1958 psi)

- Flow: from 23 / 24 l/min

- High-pressure outlets: 8 (optional up to 16)

- Filter: Bag type 5 μm (Pressurized Filter)

- Tank capacity: Without tank

- Heat exchanger: Not included

SCS 500 | OIL / EMULSION

Super Compact high-pressure system, that fits under most of bar feeders in the market. Ideal for small sliding head lathes, drilling and tapping centers or lathes of up to 11 KW of spindle power.

Features:

- Pressure: from 70 to 130 Bar (1015 to 1885 psi)

- Flow: from 16 to 24 l/min

- High-pressure outlets: 4 (optional up to 8).

- “Venting” for immediate high-pressure delivery response

- Filter: bag type 5 μm

- Tank capacity: 50 L

- Full color 7” touch-screen / User-friendly HMI (Industry 4.0)

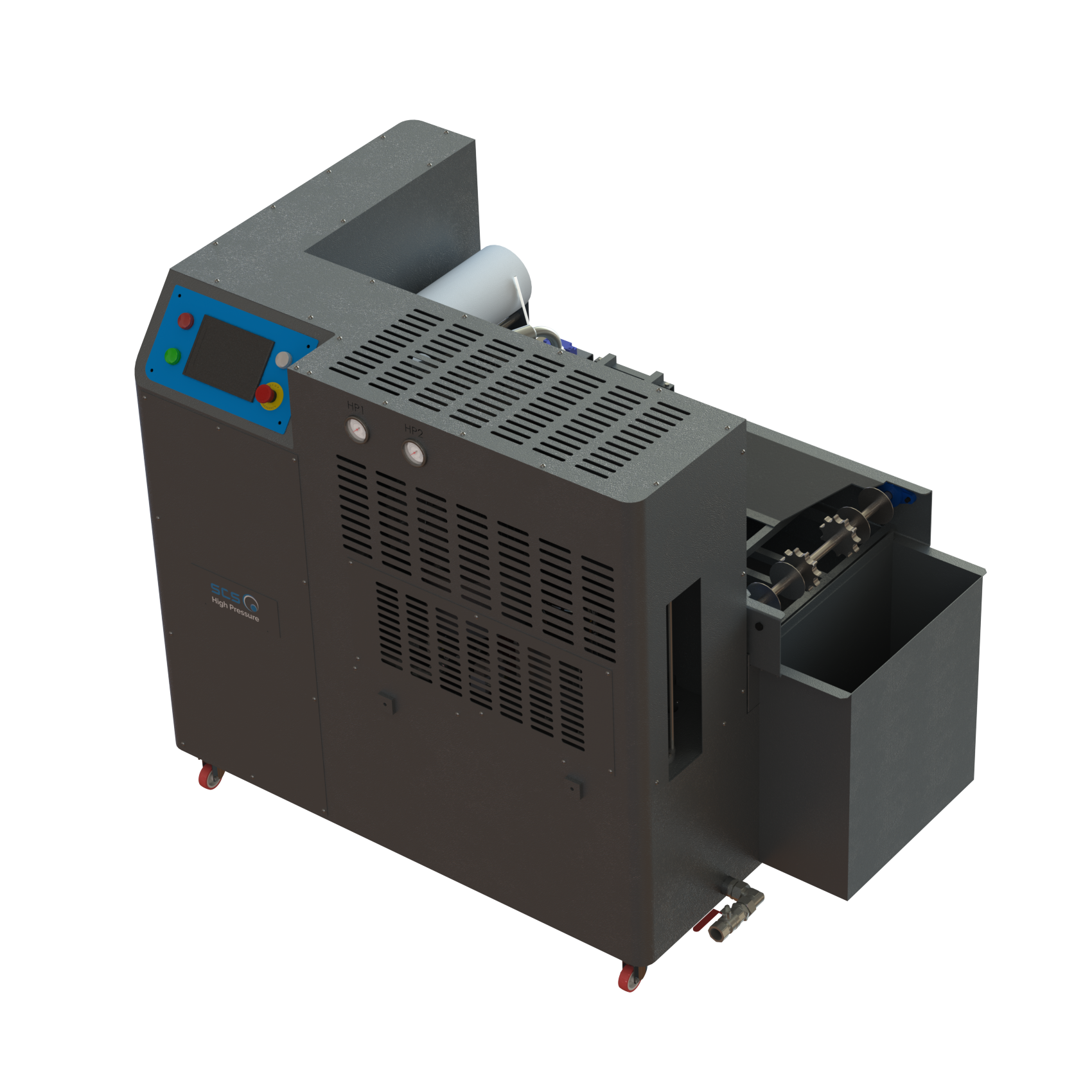

SCS 1500 | OIL / EMULSION

High-pressure system with bag filter and high capacity tank. Ideal for almost any kind of machine-tool: sliding head lathes, fix head lathes or machining centers.

- Pressure: from 70 to 135 Bar (1015 to 1958 psi)

- Flow: from 23 to 62 l/min

- High-pressure outlets: 8 (optional up to 16)

- “Venting” for immediate high-pressure delivery response

- Filter: bag type 5 μm

- Tank capacity: 180 L

- Full color 7” touch-screen / User-friendly HMI (Industry 4.0)

SCS 1900 | EMULSION

Very competitive high-pressure system for emulsion with multi-pocket flag filter and high capacity tank. Ideal for fixed head lathes, vertical and horizontal machining centers of up to 17 KW of spindle motor

Features:

- Pressure: 70 Bar (1015 psi)

- Flow: 35 / 62 l/min

- High-pressure outlets: 1 or 2

- “Venting” for immediate high-pressure delivery response

- Filter: 2 x multi-pocket textile filter of 10 μm / 2 filter lines, each with 2 filters

- Tank capacity: 180 L

- Full color 7” touch-screen / User-friendly HMI (Industry 4.0)

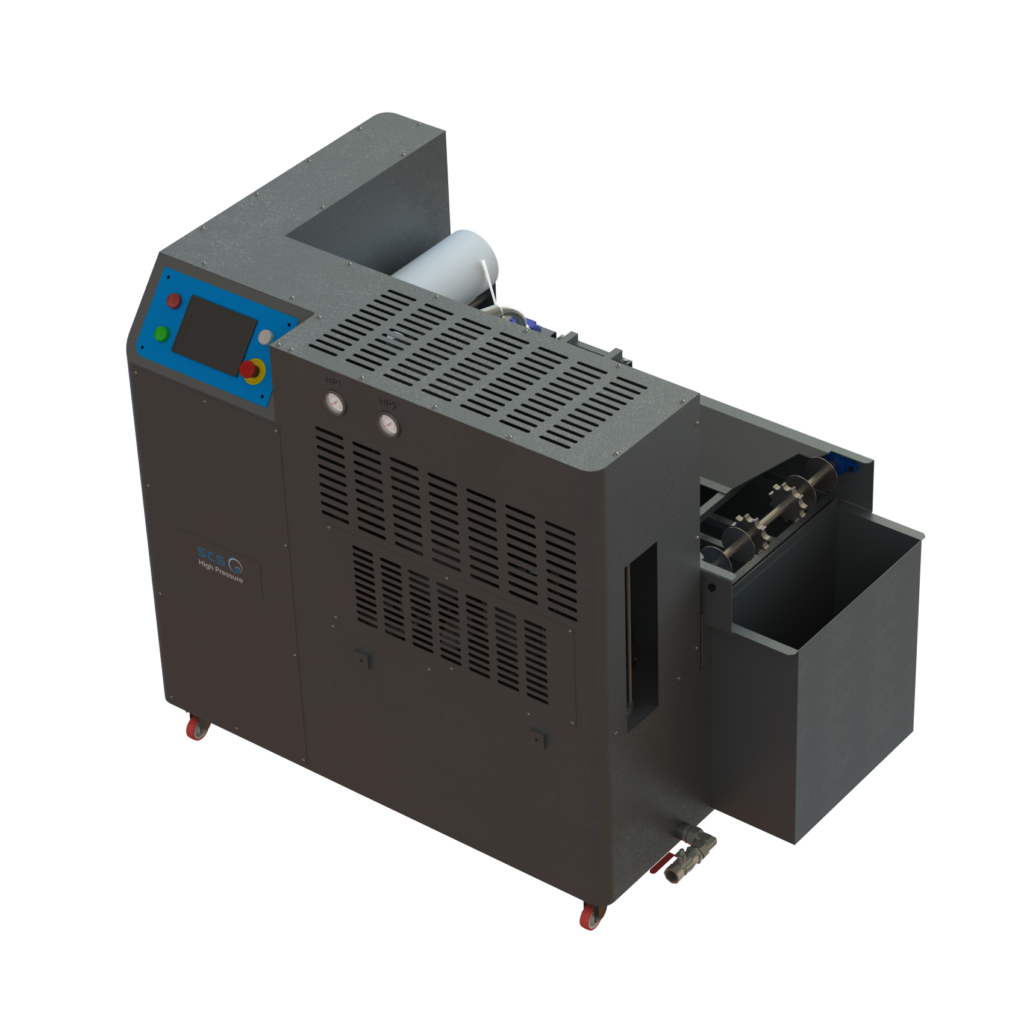

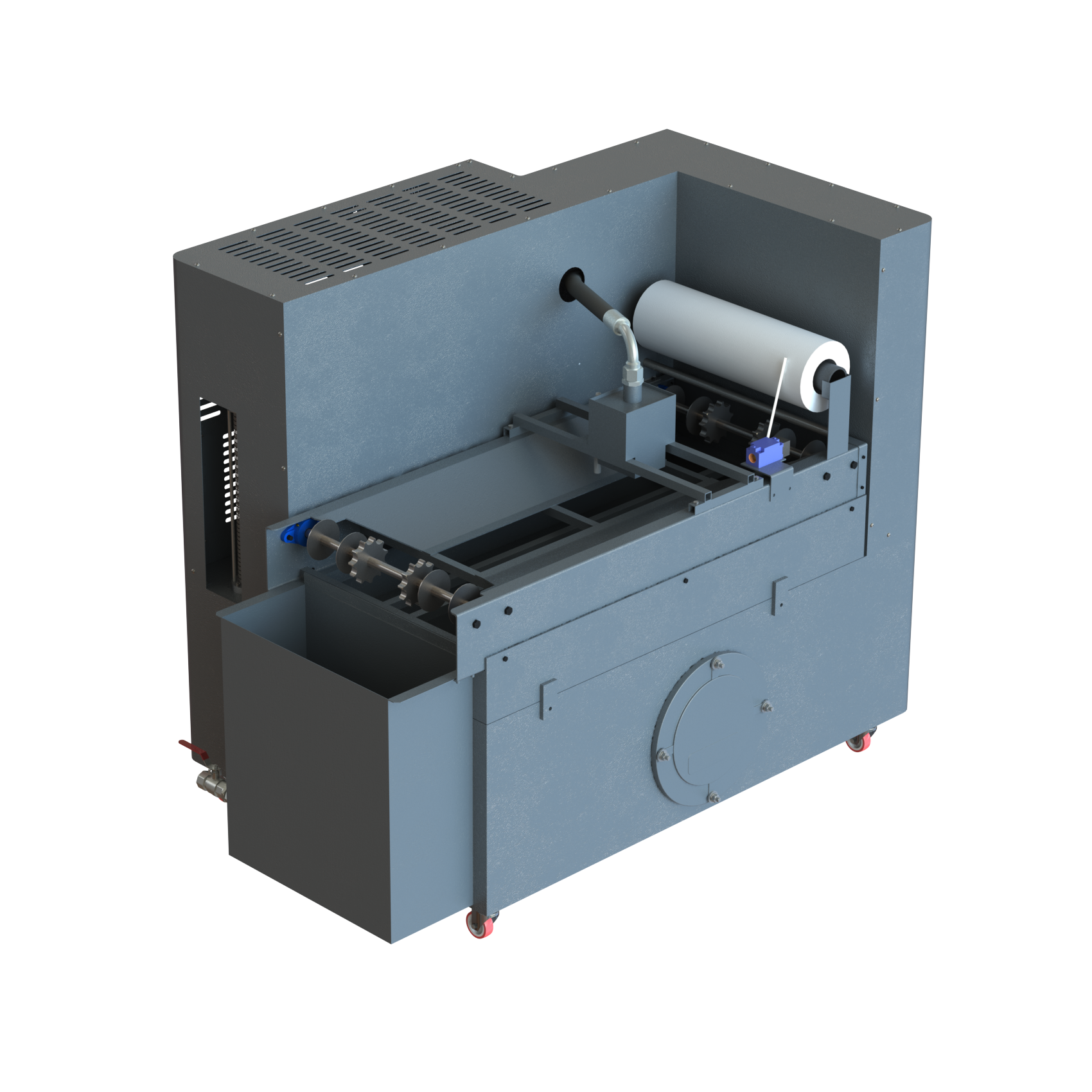

SCS 2100 / 2200 |OIL / EMULSION

High-pressure system for emulsion, with multi-pocket textile filter and available with 1, 2 pumps. Ideal for fixed head lathes with 1or 2 turrets, vertical or horizontal machining centers.

Features:

- Pressure: 70 Bar (1015 psi)

- Flow: From 24 to 62 l/min each pump

- Number of pumps: 1 or 2

- High-pressure outlets: from 1 to 2

- “Venting” for immediate high-pressure delivery response

- Filter: 2 x multi-pocket textile filter / 2 filter lines, each with 4 filters

- Optional: Self-cleaning filter. Paper band filter.

- Tank capacity: 370 L

- Full color 7” touch-screen / User-friendly HMI (Industry 4.0)

SCS 2100 pf | OIL / EMULSION

High-pressure system for emulsion, with multi-pocket textile filter and available with 3 pumps. Ideal for fixed head lathes with 3 turrets, vertical or horizontal machining centers

Features:

- Pressure: 70 / 135Bar (1015 – 1958 psi)

- Flow: From 19 / 50 l/min

- Number of pumps: 1

- High-pressure outlets: from 1 to 2.

- “Venting” for immediate high-pressure delivery response

- Filter: 2 x multi-pocket textile filter / 2 filter lines, each with 4 filters

- Optional: Self-cleaningfilter. Paper band filter

- Tank capacity: 420 L

- Full color 7” touch-screen / User-friendly HMI (Industry 4.0

SCS 2100 / 2200 PF2 | oil/ EMULSION

High-pressure system for emulsion, with multi-pocket textile filter and available with 3 pumps. Ideal for fixed head lathes with 3 turrets, vertical or horizontal machining centers.

Features:

- Pressure: 70 Bar (1015 psi) or 70 + 70 Bar

- Flow: From 19 / 50 l/min each pump

- Number of pumps: 1 or 2

- High-pressure outlets: from 1 to 2.

- “Venting” for immediate high-pressure delivery response

- Filter: 25 micron paper filter. Quick and easy filter change

- Optional* Magnetic particle separator

- Tank capacity: 420 L

- Full color 7” touch-screen / User-friendly HMI (Industry 4.0)

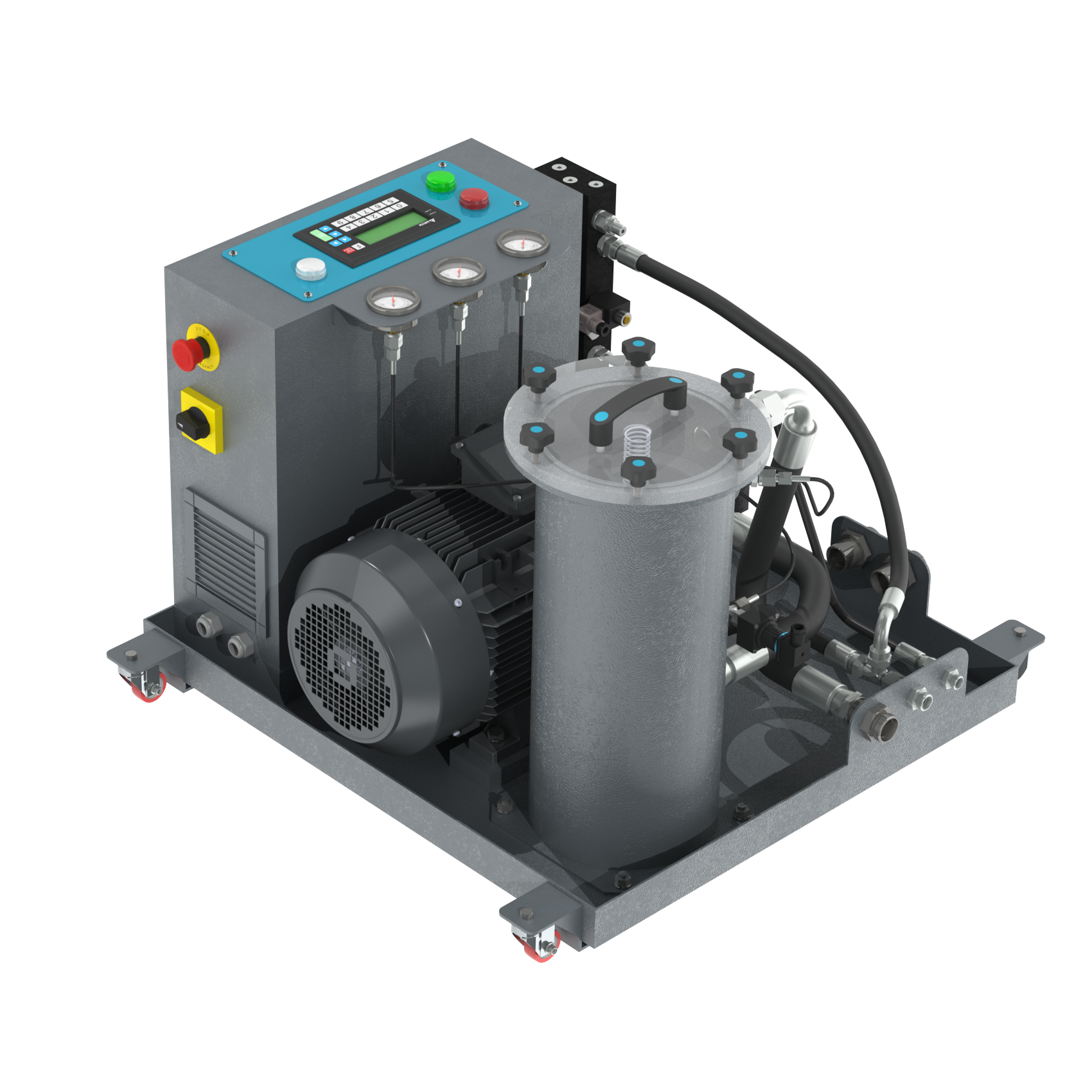

SCS 3000 | OIL / EMULSION

Universal high-pressure coolant system with bag-type filter and large tank system. Ideal for being placed parallel to the bar feeder or next to the machine-tool tank. Suitable for many types of machine-tools: sliding head lathes, fix head lathes or machining centers.

Features:

- Pressure: 70 / 135 Bar (1015 – 1958 psi)

- Flow: 23 a 24 l/min

- High-pressure outlets: 8

- “Venting” for immediate high-pressure delivery response.

- Filter: Bag type 5 μm

- Tank capacity: 120 L

- Full color 7” touch-screen / User-friendly HMI (Industry 4.0)

- Heat exchanger: Included